We can supply OEM, ODM, Sample-based customization, Design-based customization, Full customization of the sugarcane bagasse pulp molding products.

Here’s how the customization process generally works:

1. Design Submission: Clients submit design drawings or samples to us.

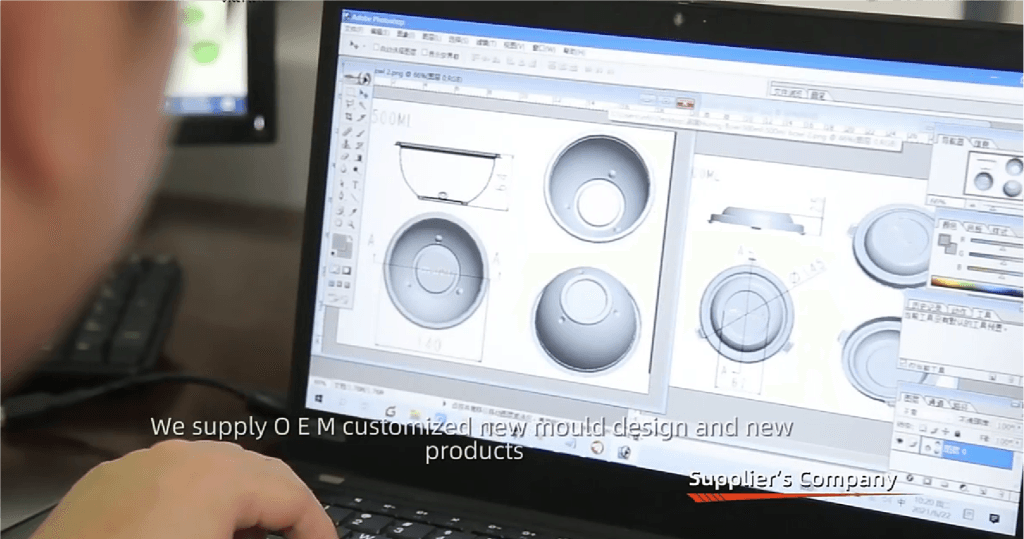

2. Customization Options: Discuss and determine the specifications and characteristics of the material to be used for production. We create prototypes based on the client’s design or sample. Discuss customization options according to the client’s needs, such as size, shape, color, or logo addition. Issue a 3-D drawing for the client confirmation.

3. Sample Approval: Before mass production, we will provide samples for client approval if needed. This needs a small sample mold and cost and may need around 7-15days.

4. Produce large production mold: After sample (if needed)or 3-D drawing confirm from the client, and both parties have reached an agreement about the order, we will made a large production mold. (This may need around 20-35days)

5. Mold Testing and Production Run: Once approved, after new mold testing and produce qualified products, the production run will commence to fulfill the order.

6. Quality Assurance: We will ensure the quality of the customized products meets the standards.

7. Delivery: After production is complete, the products are delivered to the client.

8. Minimum Order Quantity: Note that we require a minimum order quantity depending on difference products.

How to customize the sugarcane pulp molded products based on my design or sample?

Customizing sugarcane bagasse pulp molded products to your specific requirements involves several steps, which can be detailed as follows:

- Identify Your Needs: Start by determining the type of product you want to create, its intended use, and any specific requirements it must meet in terms of size, shape, and function.

- Contact the Manufacturer: Find manufacturers that specialize in custom sugarcane bagasse pulp molding. Bioleader company focuses on pulp molding eco-friendly biodegradable tableware. Contact us to discuss your ideas. Provide us with detailed specifications, including dimensions, design features, and the desired quantity.

- Design Submission: Supply the manufacturer with design files or sketches of your desired product. This may include 3D models, technical drawings, or conceptual illustrations.(This step can be worked by us too, we can supply the design and 3-D drawing for you to base your idea or samples)

- Material Selection: Work with the manufacturer to choose the right type of sugarcane bagasse pulp that meets your product’s requirements for strength, flexibility, and aesthetics.

- Prototype Development(Sample): Request the creation of a prototype (sample). This is a crucial step where the manufacturer will produce a sample of your product for review and approval. (This may need around 7-15days)

- Quality Assessment and Durability and Safety Testing: Examine the prototype to ensure it meets your expectations in terms of quality, functionality, and appearance. Make any necessary adjustments to the design or materials. If applicable, conduct tests for durability, heat resistance, and food safety to ensure the product meets industry standards and is safe for its intended use.

- Produce large production mold: After sample confirm, and both parties have reached an agreement, the manufacturer will made a large production mold.(This may need around 20-35days)

- Place an Order: Once you are satisfied with the prototype or samples, place your order with the manufacturer. Specify the quantity, delivery timeline, and any special packaging or shipping requirements.

- Production Monitoring: Stay in contact with the manufacturer during production to monitor progress and ensure that the manufacturing process adheres to your quality standards.

- Final Inspection: Before the final shipment, inspect a random sample of the finished products to confirm they meet your expectations.

- Delivery and Distribution: Coordinate with the manufacturer for delivery of the products to your specified location. Ensure you have the necessary distribution channels in place.

- Certifications and Compliance: Make sure that the custom-made sugarcane bagasse products comply with all relevant regulations and obtain any required certifications, especially if they are intended for food contact.

- Marketing and Branding: Develop a marketing strategy to promote your custom sugarcane bagasse products, highlighting their eco-friendly attributes and unique selling points.

Customizing sugarcane bagasse pulp molded products allows you to create unique items tailored to your brand and market needs while contributing to a more sustainable environment.

Xiamen Bioleader Environmental Protection Technology Co., Ltd

Professional manufacturer of pulp molding eco-friendly biodegradable tableware and takeaway food packaging! Committed to disposable degradable eco-friendly tableware, we can provide customized pulp sugarcane pulp mold products for a wide range of customers. We have developed hundreds of different products for our customers: meal boxes, plates, bowls, bowl lids, cups, fruit trays, pizza boxes, dessert holders, seafood trays, industrial packaging products, and more. We can customize embossed logos for our guests and welcome contact for more details.