Introduction

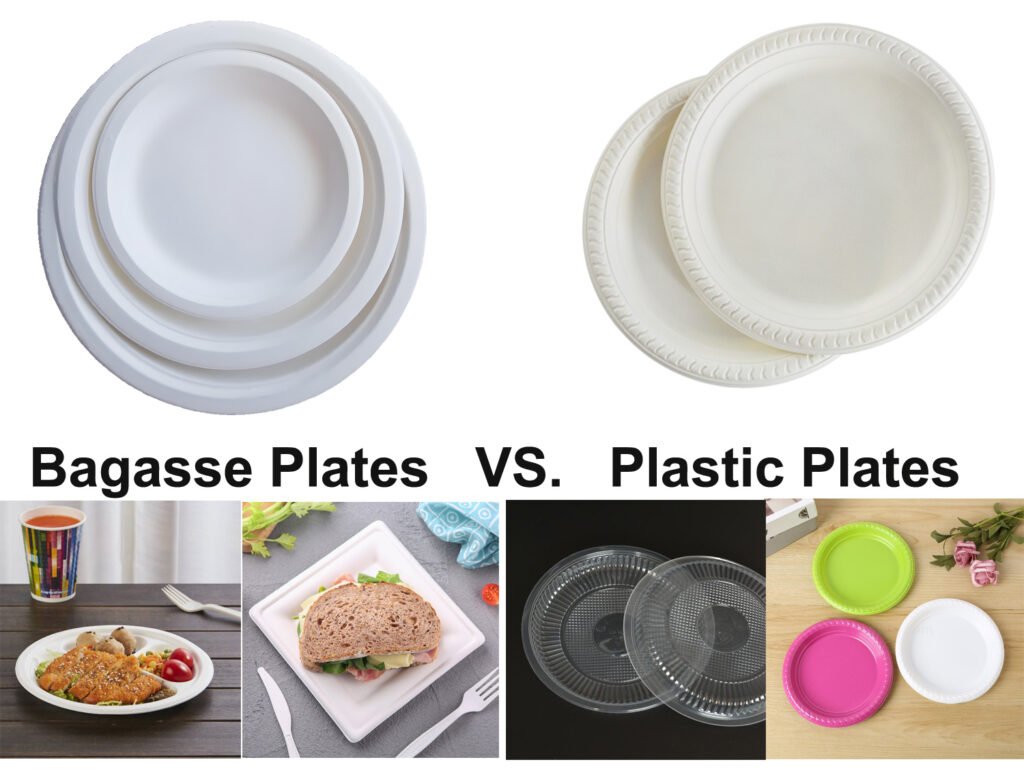

The debate over single-use disposable dinnerware has reached a tipping point in a world increasingly focused on sustainability and environmental stewardship. The choice between bagasse plates and plastic plates is no longer just a matter of convenience—it is a decision that affects our planet’s future. The answer is clear: bagasse plates, made from the fibrous residue of sugarcane, are far superior to traditional plastic plates. They offer significant environmental, economic, and health benefits, making them an ideal alternative for eco-conscious businesses and consumers.

Recent studies, such as those by the United Nations Environment Programme (UNEP) and various lifecycle assessments, have underscored the urgent need to replace plastic products with renewable, biodegradable alternatives. With bagasse plates, the entire lifecycle—from production to disposal—results in a much lower carbon footprint. In this blog, we examine the critical differences between bagasse and plastic plates, present expert data, and illustrate the practical benefits with a real-world case study featuring Bioleader’s successful use of bagasse plates in restaurants and events.

Environmental Impact

Material Origins and Production

The primary source for plastic plates is petroleum, which is a non-renewable resource that emits significant carbon and damages the environment during extraction and processing. On the other hand, bagasse is a residue from the extraction of juice from sugarcane. Wastes that were once considered useless are now turned into long-standing food ware. This upcycling of these agricultural wastes not only alleviates the pressure on landfills but further decreases the demand for fresh raw materials.

Biodegradability and Compostability

The decomposition-friendly nature of bagasse plates is one of the most advantageous characteristics. They naturally break down within 90 to 180 days under proper composting conditions as compared to plastic plates, which can take hundreds of years to disintegrate and often turn into harmful microplastics. This quick decomposition along with proper waste management helps return nutrients to the soil instead of having it set in landfills.

Carbon Footprint and Greenhouse Gas Emissions

The production and disposal of bagasse plates are consistently shown to emit much less greenhouse gas compared to plastic plates. As bagasse plates are made from renewable resources, their carbon footprint is decreased. Studies have proven that shifting from traditional sources of manufacture to bio-based sources like bagasse aids in reducing climate change through less CO₂ emission from manufacturing processes.

Economic Considerations

Cost Efficiency Over Time

Although the price of bagasse plates may be higher than the cost of plastic plates, the long-term savings offset this investment. Bagasse plates do not come with many of the hidden costs that accompany plastic waste, such as environmental penalties and costly waste removal services. An increase in the production of sustainable goods should lower costs of production due to higher consumer demand; therefore, making bagasse plates even more business-friendly.

Market Growth and Industry Trends

At present, the global market for bagasse plates is witnessing strong growth. Emerging market studies reveal that the bagasse plates industry had a valuation of nearly US$ 201.4 million in 2022 and is estimated to increase at a CAGR of 6.7% to almost US$367.6 million by 2031. The primary reasons for this growth are the increasing demand from policymakers to limit the use of plastic and changing consumer habits that prefer environmentally friendly goods. Organizations that make the switch to bagasse plates stand to gain with changing market sentiment as well as improved brand equity.

Incentives for Sustainable Business Practices

For example, governments and regulatory authorities subsidize companies that change to sustainable materials through tax incentives or grants. Companies that switch to using bagasse plates can lessen their environmental harm whilst improving their economic performance by lowering their disposal costs and enhancing their market share. The shift is consistent with wider CSR goals, which helps in attracting more consumers and eco-friendly investors.

Health & Safety

Chemical-Free Composition

BPA and phthalates are common ingredients in plastic plates that increase their risk level because they easily leach into food. Bagasse plates, on the side, are made purely from plant fibers and they are BPA-Free and PFAS-Free. They have no toxic additives and therefore offer the safest means of feeding hot or acidic food.

Compliance with Safety Standards

Bagasse plates’ serve ware category is claimed to have undergone extensive research and meets qualified international guidelines for materials in contact with food. Several researches have been done and these plates were proven to not emit toxic chemicals even in extremely hot environmental settings. Children in food service can therefore use these plates without endangering customer health. These plates serve the purpose of supporting food businesses’ strategies for healthy food while further supporting sustainability.

Consumer Trust and Brand Loyalty

There has been an increase in concern over the health risks posed by plastics which has made consumers gravitate towards safer options. Businesses that use bagasse plates build trust with their customers. This therefore means that the barriers are lowered for the company’s sustainable brand reputation, owing to the increased publicity by responsible consumers as well as the protection to consumers.

Comparison Table of the Key Differences Between Bagasse Plates and Plastic Plates

| Aspect | Bagasse Plates | Plastic Plates |

|---|---|---|

| Material Source | Sugarcane fiber (byproduct of sugarcane juice extraction) | Petroleum-based plastics (non-renewable resources) |

| Manufacturing Process | Pulp is processed and molded into plates | Extraction and polymerization, molded into plates |

| Environmentally Degradable | Biodegradable and compostable within 90 to 180 days | Non-biodegradable, takes hundreds of years to decompose |

| Non-toxic/Safe | Free from harmful chemicals like BPA and phthalates | May contain chemicals like BPA and phthalates |

| Cost | Initially higher but cost-effective long-term due to less disposal fees | Lower initial cost but higher environmental and disposal costs |

| Recycling/Disposal | Compostable in industrial facilities, reduces landfill waste | Recycling is limited; often ends up in landfills or incineration |

This table succinctly illustrates why bagasse plates are a more sustainable and environmentally friendly option compared to traditional plastic plates.

Bioleader’s Bagasse Plates for Restaurant and Party

Real-World Application: Bioleader Case Study

Bioleader is a company that has successfully switched to using bagasse plates. With Bioleader adopting the use of sugar cane bagasse, there has been a noticeable improved operational productivity, and customer satisfaction is also on the rise.

Operational Success in Restaurants

Bioleader supplied one of its flagship restaurants with sugarcane bagasse plates for both dining-in and takeout menus. The company was able to reduce its non-recyclable waste by 40% because bagasse plates do not sit in landfills forever, they break down. Furthermore, surveys have shown that more than 80% of the diners who participated said they appreciated the eco-friendly initiative and associate it with high quality and a positive brand image.

Catering and Event Applications

Bioleader has taken bagasse products to a new level at large-scale events. The company supplied cutlery, plates, and bowls made from bagasse for a corporate party attended by 500 individuals. These products functioned exceptionally well whether holding piping hot soups or cold desserts. They stood up to the event, and afterward, were sent for industrial composting where they completely disintegrated in three months. This proved the functionality of bagasse products, and more importantly, affirmed Bioleader’s commitment to sustainability.

The Bioleader case clearly illustrates that the switch to bagasse plates can result in major operational changes for the better while improving the image of a company from an eco-friendly perspective.

Implementation Strategies For Businesses

Research and Supplier Selection

For businesses looking to make the switch, the first step is to research and pick trustworthy suppliers that furnish certified bagasse products. Check the bags a supplier is selling for solid quality control procedures and hands-on certification for biodegradability and compostability.

Gradual Transition and Pilot Testing

Instead of replacing everything at once, it is more effective to start with pilot testing and then gradually phase everything out. Begin by replacing half of the dinnerware with cheaper plastic alternatives, analyze how things go and scale up the replacements if certain objectives are achieved.

Staff Training and Customer Education

Train staff on the advantages of bagasse plates and their proper disposal. At the same time, make customers aware through signage, social media, and leaflets in the store of the environmentally friendly change. Open dialogue builds trust and motivates the public to embrace the change.

Monitor, Evaluate, and Optimize

It is essential to keep track of and assess operational performance, customer care, waste, and cost savings post-implementation. Utilize these metrics to optimize working methods, rectify problems, and make the most of the bagasse by-products. Continuous communication guarantees the sustainability of the switch, providing it is done correctly.

Conclusion

Bagasse plates represent a clear win over plastic plates from environmental, economic, and health perspectives. They are made from renewable, biodegradable resources and contribute significantly less to landfill waste and greenhouse gas emissions. Moreover, real-world applications, such as Bioleader’s case study, provide strong evidence that bagasse plates not only perform well under demanding conditions but also enhance brand image and customer satisfaction.

In summary, while the convenience and low upfront cost of plastic plates might seem appealing, their long-term environmental, health, and economic costs are far too high. Embracing bagasse plates offers a pathway toward a more sustainable future—one that aligns with global efforts to reduce plastic waste and promote eco-friendly practices.

For food service businesses, transitioning to bagasse plates is not merely a trend but an essential step in meeting regulatory requirements, reducing operational costs, and building a responsible brand image. Whether used in restaurants, catering events, or large-scale parties, bagasse plates deliver on performance and sustainability. The weight of scientific data, expert opinions, and practical case studies all point to one undeniable conclusion: for a sustainable future, bagasse plates are the superior choice.

Let us commit to making the right choices—one plate at a time—so that together we can protect our planet and ensure a healthier future for all.

Source List for the Article:

- UNEP, “Single-use Plastics: A Roadmap for Sustainability”

- Razza et al., “Compostable Cutlery and Waste Management: An LCA Approach” – ScienceDirect

- Franklin Associates, “Life Cycle Inventory of Foam Polystyrene, Paper-based, and PLA Food Service Products”

- Transparency Market Research, “Bagasse Plates Market Size, Share, Demand & Outlook, 2031” – Transparency Market Research

- Nature Earth Packaging, “Why Bagasse Plates Are the Future of Sustainable Food Packaging” –

- Ibambo, “Bamboo vs. Bagasse: Choosing Eco-Friendly Disposable Dinnerware”

- Serious Eats, “How to Reduce Single-Use Plastic: Simple Steps for a Greener Kitchen” – Serious Eats