In today’s world, when environmental issues are at the forefront of consumer awareness, companies and consumers alike are increasingly looking for sustainable alternatives to conventional packaging materials. This trend is expected to continue. Packaging made from sugarcane stands out as a viable candidate among the many environmentally friendly choices that are now being introduced to the market. Packaging made from sugarcane, which is derived from a renewable resource, is being praised for its potential to lessen our dependency on fossil fuels and to decrease the negative effect that it has on the environment. However, what it is that makes sugarcane packing environmentally friendly? In what ways does it differ from traditional materials used for packing, and what are the advantages and disadvantages of using it? The purpose of this blog is to provide a full review of sugarcane packaging and its role in the search for sustainable solutions. We will investigate these topics in further depth in the next blog post.

What You Need to Know About Sugarcane Packaging

Packaging created from sugarcane is formed from the fibrous residue, often known as bagasse, that is left over after the juice is extracted from sugarcane. Bagasse was traditionally seen as a waste product and was often thrown away or burnt whenever it was produced. However, technological advancements have made it possible for it to be transformed into a valuable raw material that can be used in the production of packaging that is both biodegradable and compostable.

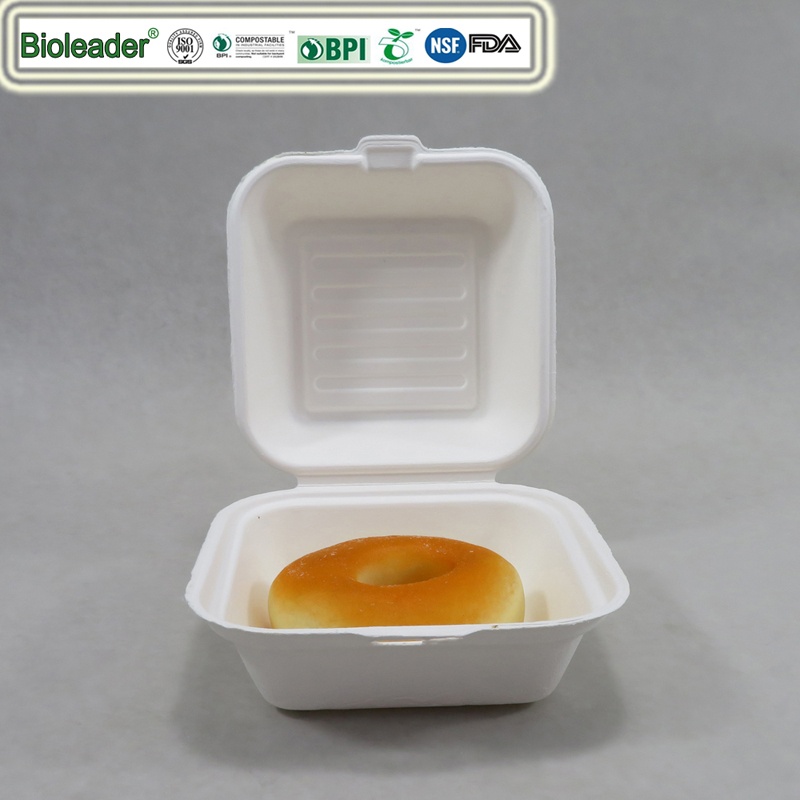

To manufacture packaging items like as plates, bowls, containers, and trays, the bagasse is first pulped, and then it is molded into a variety of shapes and sizes following the molding process. Not only are these items durable and adaptable, but they also provide an environmentally beneficial alternative to traditional materials such as plastic and Styrofoam, which are known for the environmental damage they do.

Beneficial Effects of Sugarcane Packaging on the Environment Sugarcane packaging is a renewable resource, which is one of the most significant benefits of using this material for packaging. Sugarcane, in contrast to polymers constructed from petroleum, is a crop that can be grown and harvested on a yearly basis. since of this, sugarcane packaging constitutes a more environmentally friendly alternative since it lessens reliance on limited fossil fuels.

Packaging made from sugarcane is biodegradable, which means that it may decompose naturally over time without leaving behind any hazardous residues. Compostability is another benefit of using sugarcane packaging. Furthermore, it is biodegradable, which means that it can be processed in industrial composting facilities to generate compost that is rich in nutrients. This further improves the health of the soil and reduces the amount of trash that is sent to landfills.

Reduction in Carbon Footprint: When compared to the manufacture of plastic, the production of sugarcane packaging often results in a lesser amount of carbon emissions. Additionally, throughout the growing process, sugarcane plants take in carbon dioxide, which helps to compensate for some of the emissions that are created during the processing of the sugarcane. The entire carbon footprint is reduced as a result of this consideration.

The use of bagasse for packaging helps to redirect agricultural waste away from landfills and incineration, which contributes to the promotion of a circular economy in which waste materials are recycled into useful goods.

Similarities and Differences with Traditional Packaging Materials

The following are some of the most significant distinctions that can be found between sugarcane packaging and more traditional materials such as plastic and Styrofoam:

Environmental Impact Plastic and Styrofoam are known for their environmental persistence and are generated from non-renewable petroleum resources. Plastic and Styrofoam contaminate the environment. As a result of their slow decomposition, which may take hundreds of years, they contribute to pollution and are harmful to animals. Sugarcane packaging, on the other hand, decomposes considerably more quickly and integrates more naturally into the ecosystems of various natural environments.

Generally speaking, the amount of energy that is necessary to manufacture sugarcane packaging is far lower than the amount of energy that is required to manufacture plastic. This further decreases its impact on the environment, making it a more energy-efficient choice than other existing options.

Despite the fact that the percentage of plastics that are recycled is increasing, a significant number of plastic items continue to be discarded in landfills or in the ocean. In example, it is difficult to recycle Styrofoam, and that material is often dumped in an incorrect manner. Because it can be composted, sugarcane packaging provides a more environmentally friendly end-of-life choice, while contributing to the reduction of waste and the recovery of resources.

Considerations and Obstacles to Overcome

In spite of the many advantages it offers, sugarcane packing is nevertheless confronted with a number of difficulties:

It is possible that the cost of producing sugarcane packaging will be more than the cost of producing typical plastic packaging. This is mostly due to the fact that the manufacturing process is more complicated and the scale of production that is currently being used. Economies of scale may be able to assist in lowering these costs if both the demand and manufacturing capacities continue to expand.

Composting Infrastructure: Although sugarcane packaging may be composted, there are several places that have a restricted number of industrial composting facilities available. It is possible that this will make it more difficult to dispose of and compost these items, which might result in their being dumped in landfills, where they might not degrade as quickly as they would otherwise.

In spite of the fact that sugarcane packaging is quite durable, it may not always be able to meet the performance qualities of plastic, especially with regard to its resistance to moisture and its durability. Because of this, its usage may be restricted in some circumstances, such as locations with high levels of moisture or long-term storage.

Packaging for sugarcane: What the Future Holds

There is reason to be optimistic about the future of sugarcane packaging, since it is being pushed by rising environmental consciousness and the desire from consumers for environmentally friendly goods. As a result of ongoing research and innovation in the field of material science, it is anticipated that sugarcane packaging would see improvements in both its performance and its cost-effectiveness, therefore becoming a viable solution for a wider variety of applications.

An increasing number of companies in a wide range of industries are already including sugarcane packaging into their efforts to reduce their environmental impact. Sugarcane packaging is excellent for a broad variety of goods because to its adaptability, which allows it to be used for a variety of industries, including food service and retail, cosmetics, and electronics. By using sugarcane packaging, businesses not only have the opportunity to lessen their influence on the environment, but they can also align themselves with the rising desire of consumers for environmentally friendly solutions.

Final Thoughts

In conclusion, the packaging made from sugarcane marks a big step forward in the quest toward environmentally friendly packaging solutions. Because of its positive effects on the environment, as well as its ability to cut down on waste and carbon emissions, it is an appealing alternative to the materials that are typically used. It is expected that continuous innovations and growing acceptance will drive additional improvements in the feasibility and availability of sugarcane packaging, despite the fact that obstacles still exist. With consumers and companies continuing to place a greater emphasis on sustainability, sugarcane packaging is well positioned to play a significant part in the development of environmentally friendly packaging in the future.

Productos relacionados