En pulp molding process is a manufacturing technique used to produce molded pulp packaging—a sustainable and eco-friendly alternative to traditional packaging materials like plastic or Styrofoam. This process involves converting fibrous raw materials into packaging products, such as sugarcane bagasse, recycled paper, cardboard, or natural fibers. These products are biodegradable, compostable, and recyclable, making them a popular choice for environmentally-conscious industries.

As a well-known Chinese molded pulp packaging manufacturer, Bioleader has focused on the pulp molding process for more than 10 years. This article introduces a complete production process for making disposable pulp tableware based on sugarcane bagasse pulp material.

Adquisición y preparación de materias primas

The quality of molded pulp packaging produced depends on the quality of sugarcane bagasse procured. The bagasse collected is transported to the manufacturing facility and stored there in a controlled environment to avoid deterioration.

Tablero de pulpa de caña de azúcar

Para mejorar el brillo o la blancura de la pulpa y de ciertos ingredientes contenidos se puede emplear un blanqueo controlado libre de Dioxinas Secundarias Emisoras de Toxicidad (SDET). una vez hecho esto, la pulpa se tamiza para deshacerse de cualquier contaminante que pueda estar presente, para obtener un producto final de buena calidad. En este caso, tras el procesamiento de las fibras de caña de azúcar húmedas, el producto aparece como un tablero hecho de pulpa de caña de azúcar para facilitar su almacenamiento y envío.

Proceso de fabricación de la pasta

El cartón de pulpa de caña de azúcar se tritura y se lava a fondo para eliminar la suciedad y todos los demás materiales no fibrosos. En este proceso se utilizan máquinas sofisticadas que simplemente descomponen el bagazo en pulpa bruta que se desgasta hasta quedar lisa.

Incorporación de aditivos

Muchos aditivos se eligen juiciosamente y se incorporan a la pulpa para mejorar características particulares de la vajilla como la resistencia al agua, la solidez y la flexibilidad. La inclusión de estos aditivos viene determinada por su consistencia con la pasta, así como por su capacidad de degradarse tras el uso para conservar el respeto medioambiental del producto. Por ahora, hemos aplicado revestimientos de barrera al flúor tanto para el agua como para el aceite.

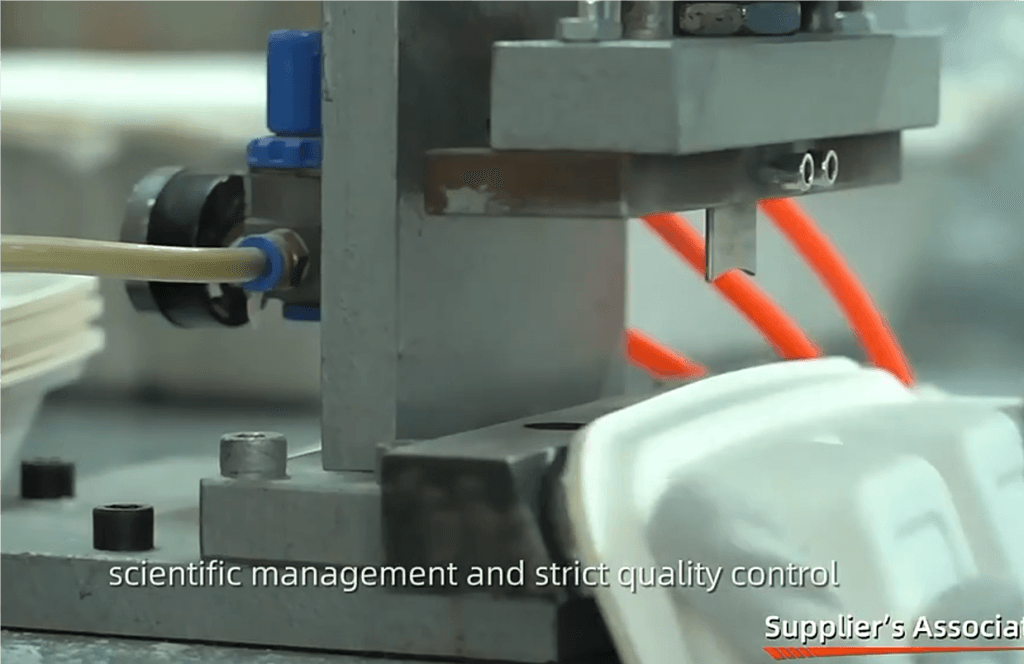

Moldeado, prensado en caliente y conformado

To make tableware such as plates, bowls, and food containers of different shapes and sizes, the machine compressed the blended pulp mass into a special column that contained sets of plates, wherein each plate had a recess containing desired shapes.

The main pulp molding process of this step: The molding procedure uses compression and heat to shape the pulp material according to the formed mold, which helps to achieve the required finish that is smooth and fine. The tableware is then exposed to a controlled drying operation whereby excess moisture critical for the structure of the product is removed by heating and dehydration built into the machine’s bulk.

Drying

The wet molded product is transferred to a drying station, where it is heated to remove moisture. Drying methods include oven drying, infrared drying, or natural air drying, depending on production scale and efficiency needs. (This step is usually connected to the previous step).

Recorte de bordes

There are currently two main types of machines prevailing on the market. one is a fully automatic machine that doesn’t have any trimming operations – towards the end of the pulp molding process the required product shape is achieved by direct trimming of the edges on the molding machine Sullivan…. The mold is fitted around the still plastic products and a scraper is used to clean the edges of the molded articles to which various fine trims of little specifications are obtained for the molded pulp packaging products.

Tratamiento y acabado de superficies

To improve the usability and aesthetic of the tableware, other than food-grade water and oil-resistant coatings on the articles, additional surface treatments are also carried out. The finishing pulp molding process will also include giving soft surfaces, edge rounding out, surface polishing, and placing permissible foods and hygienically acceptable decorations.

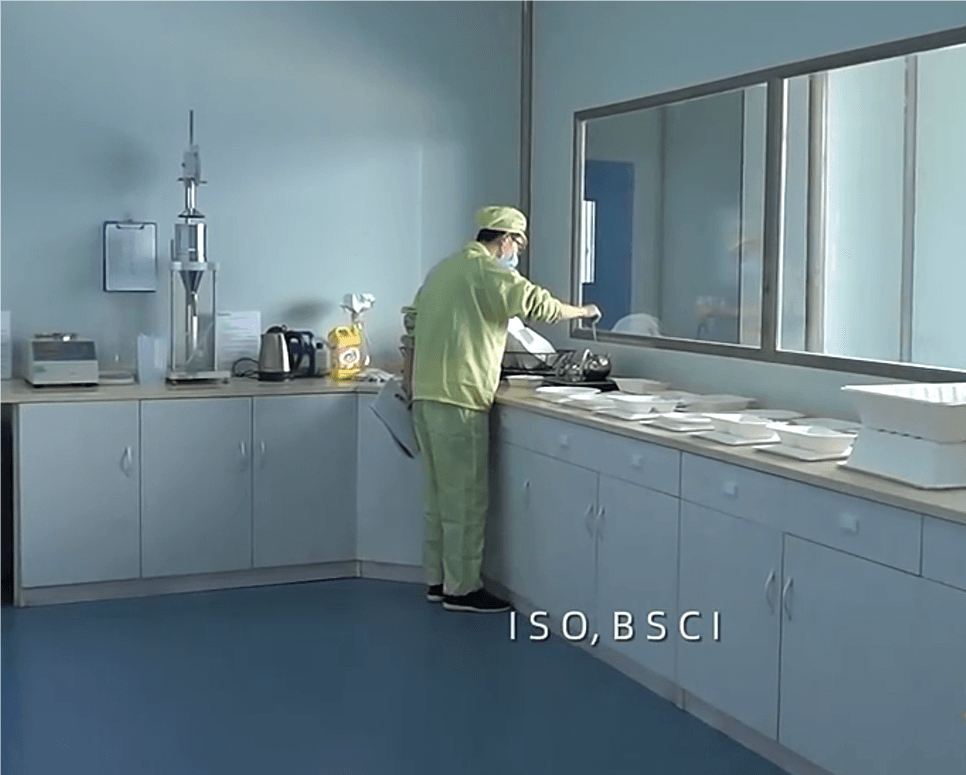

Inspección, garantía de calidad y control

Bioleader’s strict quality control measures are also taken at all stages of production to guarantee that the tableware will be of international standards regarding safety, eco-friendly, and resilience. Each molded pulp packaging product undergoes both manual and machine inspection whereby all flaws, accurate shapes and measurements as well as adherence to the design are ensured.

Detección de metales

Sometimes the screen wires might break and mix up with the product due to the use of a metal pulping screen in the product molding process. Hence, all the items made by Bioleader are metal tested to eliminate any metal parts leaking from the machine that could blend with the completed output.

Pruebas de resistencia al agua y al aceite

Most of our products are for disposable tableware use and thus need to be resistant to water and oil. Since these are plastic products, we sample some pieces of each batch to test whether they leak and soak the samples in water and oil for 6 to 12 hours.

Embalaje y marca

There is a need for molding and packaging tableware for them to withstand the rigors of transportation and storage. The use of molded pulp packaging materials is of mind for the eco-friendly concept and the design is simple and easily disposable because of the nature of the product.

Almacenamiento de productos acabados

Hay orden a la hora de organizar los productos embalados en nuestro almacén debido a los sistemas de almacenamiento de productos existentes que hay que acatar a la espera de los contenedores de exportación.

Export, Distribution, and Market Access

Containers are loaded and cargo ships set sails on directives issued by the buyers for exports. The finished molded pulp packaging tableware is kept in quality preservation conditions to avoid alteration in quality and then sold in the different explored markets. The perspective of the marketing communication is aimed at persuading households to accept the use of tableware made of sugarcane bagasse through advocacy on its ecological benefits.

Benefits of the Pulp Molding Process

· Ecológico: Reduces reliance on plastic, minimizes waste, and uses recyclable and biodegradable materials.

· Versatilidad: Can produce a wide range of products for different industries, including food, electronics, and healthcare.

· Rentable: Utilizes inexpensive raw materials and is energy-efficient.

· Personalizable: Molds can be designed for specific product requirements, offering flexibility in shapes and sizes.

This process is an essential part of creating sustainable packaging solutions, aligning with global efforts to reduce environmental impact.