As global awareness of environmental sustainability grows, eco-friendly tableware materials are becoming increasingly popular. This detailed guide explores various materials used in tableware production, emphasizing their properties, benefits, limitations, and common applications. These materials play a critical role in reducing environmental impact while offering practical alternatives to conventional plastics.

1. Bagasse (Sugarcane Pulp)

Bagasse is a cellulosic waste biomass, also referred to as sugarcane pulp, obtained from the sugar refining industry. This renewable resource serves as a sustainable substitute for tree-based papers and plastics because of its high pulping efficiency over leftover fibrous materials produced over the pressing of sugarcane juice.

Description Of Features:

- Appearance: Bagasse tableware is offered in bleached white or unprocessed brown color which looks rusty.

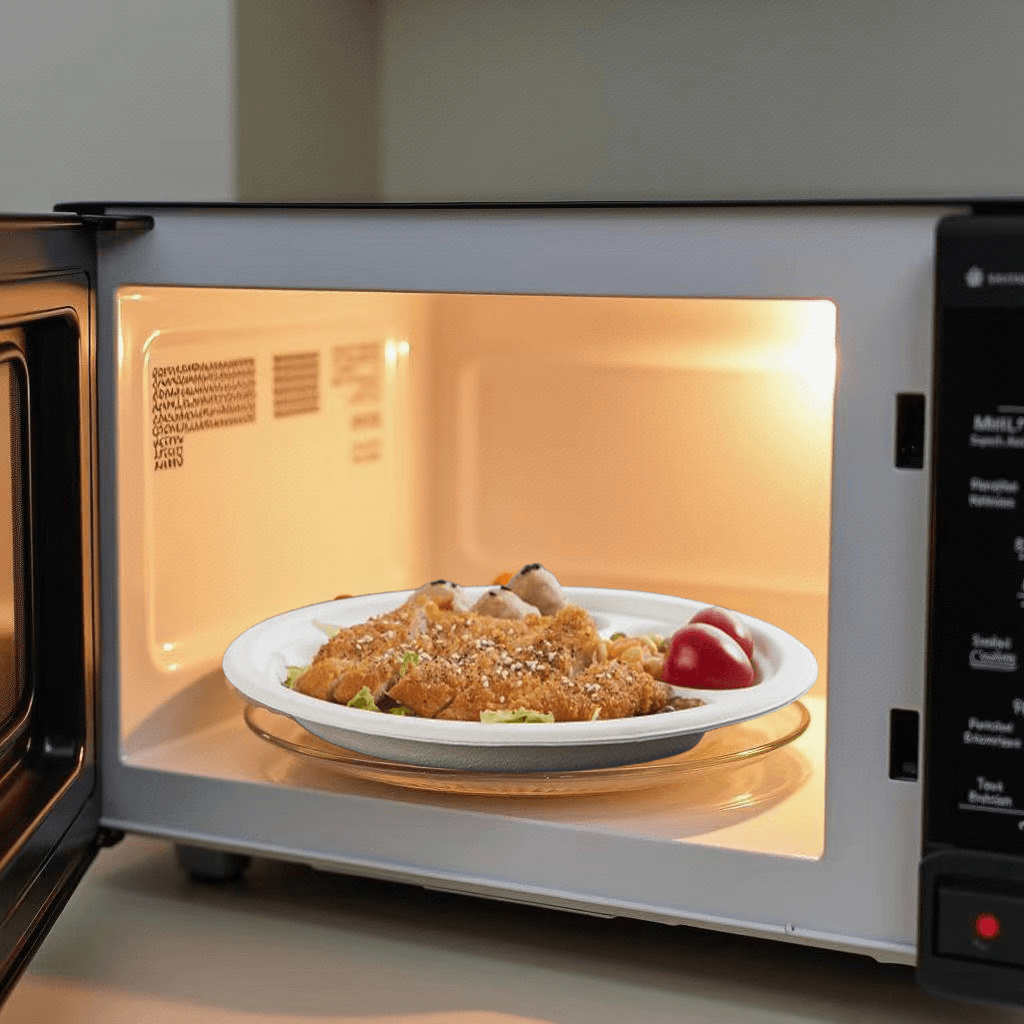

- Resisting High Temperature: Bagasse withstands temperature levels of up to 230 degrees Celsius which increases its effectiveness towards hot food and liquids.

- Safe Products when Microwaved: Their structure is not structurally compromised when subjected to microwaves or freezers.

- Compostability: Industrial systems that involve composting can use these products as a form of compoundable material. They tend to undergo decomposition in 90 days with suitable conditions.

Advantages:

- Sustainable and Ecofriendly Manufacturing: An agricultural waste product, bagasse reduces dependence on trees for raw materials.

- Anti-Oil and Water Properties: Acts as an effective moisture barrier and greasy foods resistant, making it stronger with the use of moist or oily food.

- Sturdy yet Light Weighted: Relatively lightweight for easy use but sturdy enough to serve a purpose.

Limitations:

- Sole Availability: Due to the sugarcane being seasonal, the raw goods for supply can be unstable.

- Textured Products: Bagasse products may lack the smoothness that plastic items offer.

Applications:

Bagasse is greatly used in disposable tableware or serve ware such as Plates, Bowls, and trays, especially in fast food catering events and any single-use event.

2. PLA (Polylactic Acid)

Polylactic Acid, also known as PLA, is a 100% biodegradable thermoplastic developed from foreign plant starches such as corn or sugarcane, which serves as a good substitute against petroleum-based plastic.

Characteristics:

- Appearance: Similar to PET and other plastics, PLA looks clear to a low degree of haze.

- Heat Sensitivity: PLA is usually brittle above 60 °C making it ideal for cold applications.

- Processing Versatility: Injection forming, extrusion and other conventional methods of processing may be used to manufacture PLA.

- Compostability: It is not persistent and industrial composting turns it into water and carbon dioxide.

Advantages:

- Derived from Renewable Resources: As it is derived from plants, it is from an annually replenishing source while also lessening the dependency on fossil fuels.

- Biodegradable: PLA products under proper disposal only endure short-term pollution and degrade quickly over time.

- Lightweight and Strong: It possesses an excellent strength-to-weight ratio enabling it to be used in many ways.

Limitations:

- Heat Intolerance: Due to heat intolerance, PLA cannot directly be applied to hot foods and beverages, hindering its vast use.

- Composting Requirements: There is the need for Industrial composting facilities for it to degrade which are not popularized yet.

Applications:

PLA finds its application in cold drink cups, straws, fresh food packaging and dispensable cutlery where the temperature is not elevated.

3. CPLA (Crystallized PLA)

CPLA is a variant of PLA that has been modified through crystallization, further improving its mechanical traits and heat tolerance.

Characteristics:

- Appearance: CPLA products have a matte finish, which is opaque and is more durable than standard PLA products.

- Thermal Properties: They can endure temperature ranges of 90°C Celsius making the CPLA ideal for serving hot drinks or food.

- Eco-Friendliness: CPLA preserves PLA’s ability to serve as a compostable material.

Advantages:

- Enhanced Heat Resistance: CPLA materials are perfect for hot drinks and hot meals which was a big downside for PLA.

- Durable: Compared to normal PLA, CPLA is much stronger, making it less prone to bending or breaking.

Limitations:

- Higher Cost: The cost of the CPLA products is relatively high because incurring the crystallization process makes the normal PLA product expensive as well.

Applications:

In a variety of heat-resistant tableware applications such as disposable utensils, covers for hot beverages, and other serving items, CPLA is preferred.

4. Cornstarch

Cornstarch-based tableware is made by processing corn into a biodegradable material. It is a natural alternative to synthetic plastics.

Characteristics:

- Appearance: As a cornstarch-sourced product, it is opaque and has a reasonably smooth surface.

- Heat Resistance: It can adapt to warm foods but there are restrictions applied to high-heat applications such as microwaves.

- Degradability: They are fully biodegradable and compostable but in certain conditions only.

Advantages:

- Low Environmental Impact: Cornstarch is a resource that can be recycled sustaining minimum environmental costs.

- Safe for Food Contact: Non-toxic products and do not contain detrimental chemicals.

- Affordable: Easy to source and cheap when manufactured in bulk quantities.

Limitations:

- Limited Durability: Cornstarch products can be brittle and easily break.

- Restricted Temperature Applications: Not appropriate for hot foods or liquids.

Applications:

Cornstarch is used to manufacture disposable food containers, plates, cups, and cutlery where there is in biodegradability requirement.

5. Paper Food Packaging

Paper packaging, including paper bowls, cups, and food boxes, is a versatile and widely adopted material for eco-friendly food service.

Characteristics:

- Appearance: Customizable with printing and branding, paper packaging is highly adaptable.

- Heat Resistance: Special coatings can make paper heat-resistant and suitable for hot foods and beverages.

- Recyclability and Compostability: Uncoated paper is recyclable and compostable, while coated versions may require specialized recycling.

Advantages:

- Renewable Material: Made from trees, with options for sustainably sourced paper.

- Customizable: Easily printed with designs and branding, offering high marketing value.

- Lightweight: Easy to transport and store.

Limitations:

- Durability: Requires coating or lining for liquid or greasy foods, which can impact recyclability.

Applications:

Paper bowls, cups, and food boxes are common in takeout services, cafes, and fast-food chains, offering a sustainable and versatile packaging solution.

6. PET (Polyethylene Terephthalate)

A type of strong and transparent plastic that can be recycled is PET, which has a broad range of applications. Although it isn’t compostable, it does have a lot of benefits in terms of making useable materials for newer products through recycling.

Characteristics:

- Appearance: A see-through structure that is perfect for giving a clear view of the inner material.

- Thermal Characteristics: Effective for cold storage, but malleable above more than 70 degrees Celsius.

- Durability: Extremely resistant to breakage and impact.

Benefits:

- Recyclable: PET is one of the top plastics used around the world making recycling a viable option when utilized correctly.

- Barrier Properties: Moisture and gases are formidable barriers and can significantly jeopardize food storage and its nutrients so this container strengthens gas and moisture and protects the food.

Disadvantages:

- Heat Sensitivity: Not effective if used in any hot applications.

- Recycling Challenges: To fully be sustainable good recycling systems are needed.

Applications:

Water bottles, cold drink cups, and food packaging materials rely on the visibility of the products and the preservation of contents.

7. PP (Polypropylene)

Because of its outstanding thermal and chemical resistance, Polypropylene is a hard and adaptable type of plastic and is commonly used to make reusable crockery.

Characteristics:

- Appearance: It can be semi-opaque or transparent depending on use.

- Heat Resistance: Can withstand microwave and freezing conditions.

- Chemical Stability: Resilient against oil, fat and most chemicals.

Advantages:

- Microwave and Freezer Safe: Offers suitability to different temperature qualify ranges.

- Recyclable: Has significant waste reduction by being able to turn into new products.

Disadvantages:

- Non-Biodegradable: While recyclable, it is not a natural decomposer.

Applications:

To microwave food, boxes for storage as well as tableware that is reusable.

8. PS (Polystyrene)

This type of plastic is arguably the least eco-friendly but is abundantly available being that it is cheap to manufacture. It is also commonly used for disposable food containers, cups, and trays but only in foam form.

Characteristics:

- Appearance: It is transparent or foamlike depending on the type of product.

- Heat Resistance: Can withstand warm temperatures but is not recommended for high heat conditions.

- Durability: Its thermoplastic structure makes it very brittle and easy to break.

Advantages:

- Cost-Effective: It is very easy to manufacture making it pretty much free to use.

- Lightweight: Does not add extra weight when being transported.

Limitations:

- Environmental Impact: Cannot be easily recycled and due to its non-biodegradable nature, the post-consumer waste remains in landfills and oceans.

- Health Concerns: Heated styrene releases a toxic chemical into the environment which can be detrimental to one’s health.

Applications:

PS seems to not only be the culprit when it comes to environmental destruction but can also be harmful to human health.

Conclusion

Eco-friendly tableware materials such as bagasse, PLA, CPLA, Paper and cornstarch provide sustainable alternatives to conventional plastics. These materials offer biodegradability, compostability, and reduced reliance on non-renewable resources. On the other hand, recyclable options like PET and PP remain vital for applications requiring durability and visibility. Businesses and consumers can make environmentally responsible choices by understanding the detailed characteristics, advantages, and limitations of these materials.